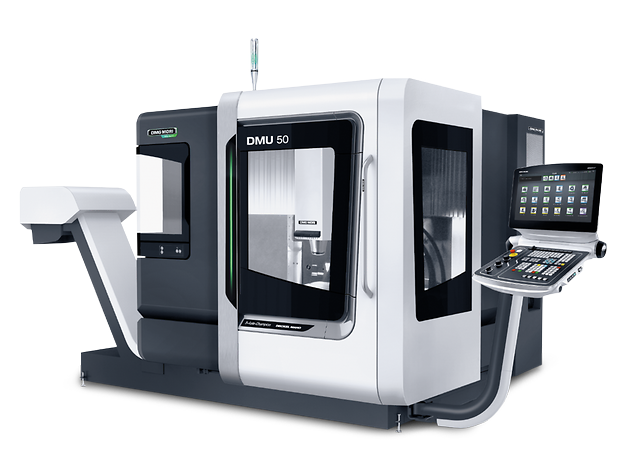

CNC Machining

Sensor Systems LLC is thrilled to announce a new product line available for your machining needs. Since 2018, we have worked with DMG MORI, a worldwide leader of CNC machines, to bring turning and true 5-axis milling capabilities in house to meet our customers requirements.

Please Contact us to discuss your CNC needs and our team is ready to support.